AES Tech is advancing the commercialization of optimized materials, stacks, systems, and control solutions for ammonia electrolysis through dedicated research and development.

The principle of liquefied ammonia electrolysis

involves the electrochemical decomposition of ammonia (NH₃) using an electrolyte and electrodes to produce hydrogen (H₂) and nitrogen (N₂). This process is a highly efficient and eco-friendly method for hydrogen production, making it an attractive technology for clean energy solutions.

liquefied ammonia is introduced into an electrolytic cell along with an electrolyte. When an electric current is applied, the following reactions occur:

Chemical Structure of Ammonia

- Ammonia is composed of nitrogen (N) and hydrogen (H), making it an ideal source for hydrogen extraction.

- It can be decomposed with relatively low energy input, enabling efficient electrochemical reactions.

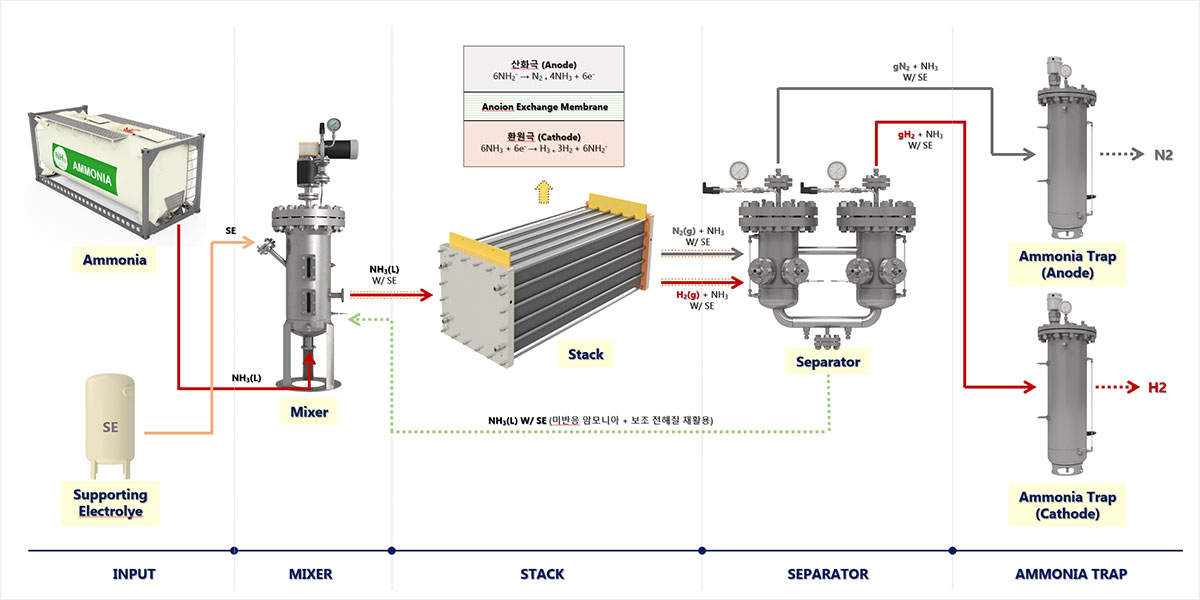

Basic Structure of AES Tech System

AES Tech is developing a system that efficiently extracts hydrogen through electrolysis of anhydrous liquid ammonia.

The system's structure is designed to achieve optimal performance and stability.

-

High Electrolytic Performance

- Enhanced Electrolytic Ammonia Production : High-purity anhydrous liquid ammonia is used to maximize the efficiency of the electrolysis reaction.

- Special Supporting Electrolytes : Supporting electrolytes such as NaNH₂ or KNH₂ are employed to enhance the electrolytic performance of ammonia.

- Optimized Membrane Technology : The system supports both cation and anion exchange membranes, offering flexibility to adapt to diverse electrolytic conditions.

-

High Energy Efficiency

- Ammonia Recycling System : Unreacted ammonia is efficiently recovered and recycled, minimizing material waste and ensuring sustainability.

- Thermal Management : The heat generated during electrolysis is effectively managed to reduce energy loss.

- Optimized Operating Conditions : The system operates under low-temperature (10°C) and high-pressure (7 bar) conditions to reduce energy consumption while maintaining high productivity.

-

Advanced System Balance

- Gas Separation and Purity Management : Hydrogen and residual ammonia are effectively separated, producing high-purity hydrogen while recycling ammonia.

- Fluid and Reaction Balance Design : Uniform fluid flow and reaction conditions are maintained to maximize system performance.